Over 2 billion tons of waste is generated each year. World Bank estimates yearly waste will grow approximately 3.5 billion tons by 2050. With waste production steadily increasing, Juno offers new life to the trash and garbage produced every day. Accepting residential and commercial waste, Juno fits into the current waste and recycling landscape, with no behavior change required from consumers.

Our History

2011

Research & Design

The Juno team began to successfully process used paper cups to recover paper fibers. The team then realized the supply chain challenges of collecting only paper cups, and pivoted to focus on running all waste from fast food restaurants, leading to successfully processing small batches of waste from both fast food restaurants and amusement park bathrooms.

2013

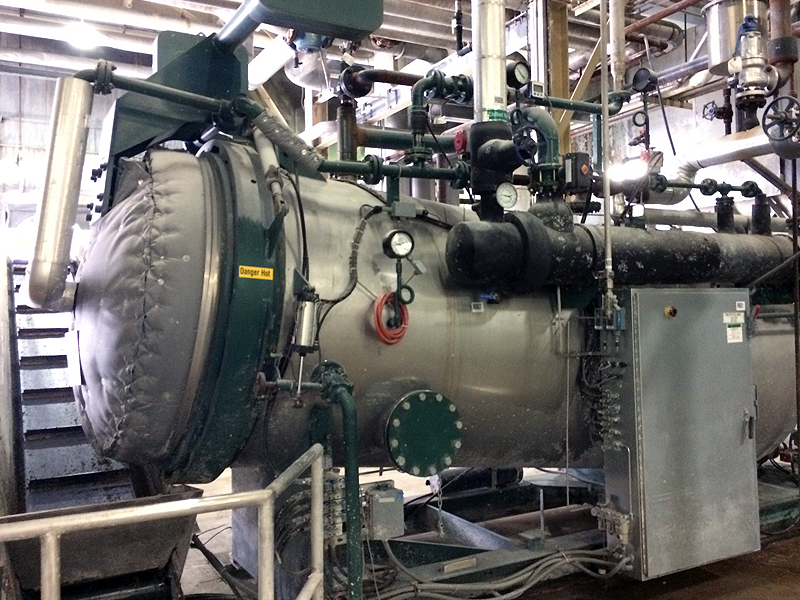

Pilot Facility

The pilot 6-ton capacity Juno waste processing system was built and proven to process waste from fast food restaurants, office buildings, airports, and amusement parks. This pilot was able to process hundreds of batches of waste, generating clean paper fiber that was able to be made into new paper products.

2015

Engineering & Design

Juno designed and engineered a 70,000-ton capacity and 300,000-ton capacity waste processing system viable for the U.S. and EU. This Juno® operating model was developed to integrate seamlessly within the existing solid waste industry infrastructure.

2018

Commercialization

Juno invested and began development on a 70,000-ton capacity waste processing system in Oregon (U.S.).

2020

Construction

The Toledo, Oregon Juno site is finished construction and prepared to receive feedstock from surrounding areas. Juno also begins accepting residential waste in addition to commercial.

2021

Operations

Toledo, Oregon Juno operations begin running 24/7. Recovered sanitized paper fiber, Juno™ Fiber, is sent to a neighboring Georgia-Pacific containerboard mill, and made into new paper products.

2022

Operations

Juno kicks off second site engineering internationally.

Backed by the expertise & industry

knowledge of manufacturing leader, Georgia-Pacific

Through Georgia-Pacific, Juno is able to leverage a nationwide network of various manufacturing facilities – aiding in resourcing and knowledge-sharing as Juno scales commercialization.

©2024 Georgia-Pacific LLC. All Rights Reserved.

| Privacy Policy | Terms of Use | GP.com | GPPackaging.com