Juno® Technology LCA Reveals Carbon Reduction Potential

January 16, 2024

Communities around the globe have been looking for ways to manage residual waste that have a lower environmental impact than alternatives like landfill and energy-from-waste. We think Juno can be a solution that provides a lower life cycle carbon impact compared to other similarly scaled waste treatment options. According to a recent third-party Life Cycle Assessment (LCA), Juno could reduce carbon by up to 1 tonne for every tonne it processes. The assessment was conducted by Sphera Solutions¹, a leader in consulting services focusing on Environmental, Health, Safety & Sustainability (EHS&S). The assessment measures Juno’s potential impact compared to municipal solid waste landfills and energy-from-waste (EfW) disposal methods in the United Kingdom, United States and Australia using ISO 14044:2006 standards. Dive in to discover everything you need to know about Juno’s LCA and its findings.

Understanding the Life Cycle Assessment (LCA)

A Life Cycle Assessment (LCA) is a compilation and evaluation of the inputs, outputs, and the potential environmental impacts of a product system throughout its life cycle.² When evaluating waste treatment options, it is a way to look at the contribution to the carbon life cycle of the waste for each waste treatment process.

Sphera completed a bin-to-grave LCA of our Municipal Solid Waste (“MSW”) processing system in accordance with ISO 14044:2006. The report went under further critical review by three outside experts in accordance with ISO/TS 14071:2014. This allowed Juno to compare our results to other waste treatment options using a standardized and consistent method.

Comparing Juno to Landfills and Energy-from-Waste

Juno uses a patented wet separation and processing solution to capture previously unrecovered paper fibers, metals, and plastics to be reclaimed for new, beneficial uses, and can convert food into renewable biogas. We like to compare Juno Technology to the alternatives of landfill and energy-from-waste because these two alternatives are often able to take a similar scale and type of residential and commercial solid waste.

To measure Juno Technology’s impact compared to these alternatives, Sphera Solutions used Global Warming Potential (GWP)³. The most common measures of GWP are the 20-year and 100-year impact, often called “GWP20” and “GWP100”.

The Results

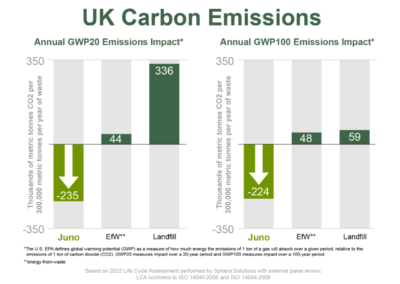

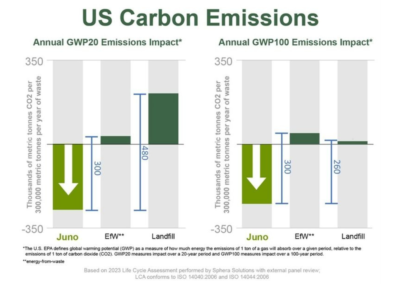

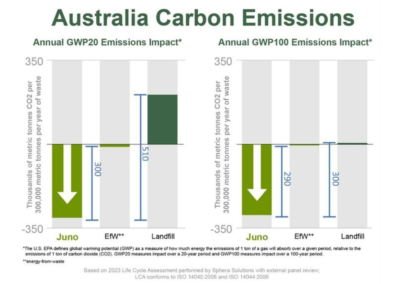

So, how did Juno stack up against landfills and energy-from-waste facilities? The findings of the LCA revealed that, in the UK, Juno could reduce nearly 800 kilograms of CO2e for every tonne processed compared to landfill and energy-from-waste using both a GWP20 and GWP100 model. That is a net impact of up to ~580,000 mt of CO2e (GWP20 inclusive of biogenic carbon) or ~280,000 mt CO2e (GWP100 inclusive of biogenic carbon) reduction compared to landfill for each year a Juno facility processes its annual capacity of 300,000 metric tonnes. According to the Environmental Protection Agency’s (EPA) Greenhouse Gas Equivalencies Calculator, this is equivalent to CO2 emission avoided by approximately 638.5 million pounds of coal burned or greenhouse gas emissions avoided by about 21.6 million incandescent bulbs switched to led, when using a GWP20i model. Our results in the US and Australia are even better than the UK!

Corresponding impacts in the U.S. and Australia are illustrated in the graphs.⁴

Since the first Juno commercial unit began processing local solid waste in Toledo, Oregon (U.S.) in May of 2021, our technology has yielded some impressive outcomes. In its first year of operation, Juno Oregon nearly tripled landfill diversion rates in Toledo. Future, more expansive Juno systems will be capable of processing 300,000 metric tonnes of waste per year using additional sorting equipment. These facilities will also be able to capture biogas, driving potential diversion rates to 90 percent of waste processed.

The difference Juno makes versus landfill or waste to energy largely comes from the recycle-first strategy. Recycling reduces carbon impact by lowering the amount of energy required to extract and process raw materials into products. The recycled materials substitute virgin materials and often require less total energy to be turned into a new product compared to virgin materials.⁵ By recovering and recycling food, paper, rigid plastics, and metals, before producing an engineered fuel, Juno can give many products a second life by putting them back into the recycled commodity market or used beneficially to run the Juno plant. We can recover around 65% of MSW material before we start making engineered fuel. Additionally, if the engineered fuel is consumed onsite, we can power all the plant’s electricity needs and provide renewable energy back to the electricity grid.

With the promising results from our recent LCA, Juno is eager to bring its innovative waste management solution to more communities. As we continue our journey, we look to help communities benefit from more sustainable waste management practices.

Sources

¹ Based on 2023 Life Cycle Assessment performed by Sphera Solutions with external panel review; LCA conforms to ISO 14044:2006.

² ISO 14040:2006, section 3.2

³ The U.S. EPA defines global warming potential (GWP) as a measure of how much energy the emissions of 1 ton of a gas will absorb over a given period, relative to the emissions of 1 ton of carbon dioxide (CO2). GWP20 measures impact over a 20-year period and GWP100 measures impact over a 100-year period.

⁴ GWP20 and GWP100 impacts across U.K., U.S., Australia.